All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: Distillery Grains, DDGS, WDGS, Alchol residues, Spent grains, Spent rice grains, Brewery wastes, Yeast waste, Corn Syrup, Grains Cake, Corn residues, Yeast waste, Yeast sludge, Yeast Residue, Winery residues, Wine sludge, Low temperature drying, Drying less than 70 Degree temperature

Before Drying

After Drying

Distiller's grains, also known as distiller's dregs, are the residues left after the use of rice, wheat, sorghum, etc. in the brewing industry. Including beer distiller's grains, white distiller's grains, alcohol distiller's grains, etc. Brewer's grains, the main byproduct of beer industry, is the residue of soluble carbohydrates extracted from seeds by fermentation with barley as raw material; distiller's grains are the residue of alcohol fermentation with sorghum, corn, barley and other pure grains; alcohol distiller's grains are the residue of alcohol (alcohol) production with corn as raw material. Distiller's grains are rich in protein, fat, crude fiber, vitamins, amino acids and micro elements; the protein content of distiller's grains and alcohol's grains is more than 30%, and the protein content of beer's grains is even more than 48%.

Distiller's grains are high-quality feed materials. After processing, they are not only suitable for feeding chickens, pigs, ducks and cattle, but also can be used in various feed yeast and biomass plants, and are also good carrier materials for feed additives. However, for a long time, the utilization rate of distiller's grains is not high, the main reason is that distiller's grains are high in humidity and viscosity, and contain a lot of cell water, so traditional drying is difficult to achieve the desired effect.

Our company develops and produces "Rotary harrow three cylinders multiple-loop" high humidity and high viscosity series distiller's grains dryer. Due to the adoption of more than 125 national patent technologies, such as "low temperature and large air volume", "three-stage hot air automatic distribution", "three-stage steam emission" and so on, it ensures that the protein, vitamin, amino acid and other nutrients in the distiller's grains do not lose or deteriorate after drying. The finished products are well matched and of good quality. After being put on the market, they are welcomed by the majority of users. The equipment is reasonable in design, space saving, high efficiency and energy saving, with a capacity of more than 100t / d. it has become the first choice of large-scale drying equipment for many famous brewing enterprises at home and abroad.

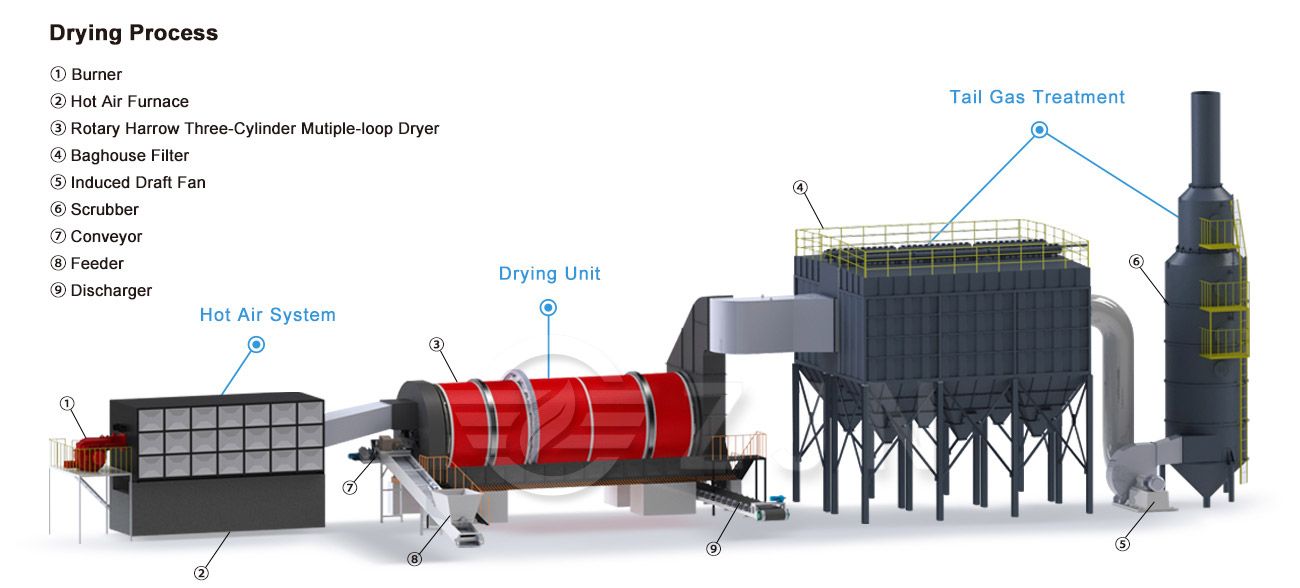

Distiller's Grains and DDGS dryer mainly consists of hot air equipment, rotating cylinder, high speed dispersing equipment, guiding and lifting boards, transmission device, conveying equipment, reducer, supporting device, sealing device, induced draft fan and other components.

It is rotary harrow triple-stage multi-loop drum drying equipment. There are three level drying processes. The process design are different with each other, to meet the material water content fluctuations at all stages. It can rapidly dry the distiller's grains and DDGS dryer from above 80% moisture content residues to below 10%. The color and nutrition will be well kept.

The special patent guiding and feeding system and material transporting trend technology overcome the "wind tunnel" phenomenon of traditional dryer. The thermal utilization rate improved, energy consumption reduced about 20%. It perfectly met different users’ requirements for particle size and moisture of dry distiller's grains and DDGS.

Grains and dregs are the surplus by-products produced in the production process of food or agricultural products processing, wine making and other industries, which are rich in material resources. According to the data statistics, the annual production of dregs in China is on the rise. If it is not handled in time, it is not only easy to ferment, rot, stink, breed mosquitoes, cause serious pollution to the environment, but also increase the production cost of enterprises. However, due to the rich organic matter, nitrogen, phosphorus, potassium and other mineral trace elements needed for crop production, as well as a large number of carbohydrates, crude protein, crude fat and crude fiber, it is very suitable for livestock feed.

The dregs dryer can quickly dry the materials with moisture content of about 80% to about 10%, greatly reducing the moisture content in the materials, reducing the volume of materials, and facilitating the subsequent transportation and storage. The materials dried by the dregs dryer can be further recycled, which can not only turn industrial waste into treasure, but also reduce environmental pollution, and improve the added value of dregs products

The structure design of the dregs dryer is reasonable, which is mainly composed of hot blast stove, feeding device, dryer body, discharging device, induced draft fan, dust removal equipment, power distribution cabinet, etc.

Its technological process: hot blast stove is the place to produce heat energy. The fuel is added into the hot blast stove to produce high-temperature heat medium through combustion, which provides continuous and stable heat for the main body of the dryer. Then, the feeding device (belt conveyor, seal scraper conveyor or screw conveyor) evenly and continuously sends the materials into the dryer. The heat exchange between the material and the high-temperature heat medium is carried out inside the cylinder, so that the moisture in the material is evaporated, and the material changes from high humidity and high viscosity to non humidity and non viscosity. The materials meeting the drying requirements are transported out through the discharging device for unified packaging and loading. The flue gas, dust and other gases generated in the drying process are transported to the dust removal equipment through the induced draft fan for purification, filtration and dust reduction, so as to achieve the gas emission standard. The whole drying production line is integrated to complete the drying of materials.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

Brewer's grains (grains), alcohol distillers' grains (residue), alcohol dregs, potato dregs, potato dregs, cassava dregs, starch dregs, medicine dregs, vinegar dregs, soy sauce dregs, penicillin dregs, antibiotic dregs, western medicine residue, saccharifying enzyme dregs, fermented bacteria dregs, sugar residue, algal dregs, tea residue, sugar dregs, sugarcane bagasse, apple pomace, pear residue, tomato dregs, fermented feed, palm residue, coconut peat, coco coir pith, sugar beet pulp, maize silage, corn silage, cassava starch, alcohol plant projects alcohol distillery supplier's all kinds of grain, DDGS,bean dregs etc

It can be widely used in breweries, feed factories, pharmaceutical factories, starch factories, food processing plants and other industries.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. Equipment structure

The equipment adopts a three sleeve structure, that is, three cylinder sleeves of different sizes are embedded together, which reduces the length of the equipment, reduces the actual floor area, and greatly increases the storage space inside the cylinder and increases the processing capacity of the equipment.

2. Equipment operation

Fully automatic operation, high degree of intelligence, simple and convenient operation, 24-hour continuous operation.

3. Heat distribution

In the process of drying, the temperature and air volume can be adjusted according to the moisture content of the dregs in different stages.

4. Equipment material

The equipment is made of materials with high temperature resistance, corrosion resistance and wear resistance. The equipment has good quality, stable performance and low failure rate. Greatly extend the service life of the equipment.

5. Energy saving and environmental protection

The whole production process of the system is tightly sealed, which can effectively reduce gas leakage and heat dissipation, and has good energy saving and environmental protection performance.

6. Heat source range

The heat source of the equipment can be gas, coal, electricity, oil, biomass particles, boiler flue gas waste heat resources and steam, etc.

7. The finished product is controllable

The quality of the dried dregs is even, and the state and size of the dregs can be adjusted according to the user's requirements to facilitate the next use.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.