All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: Coal slime, Peat, Petroleum coke, Lignite coal, Coal sludge, Brown coal, Minerun coal, Coal Power, Charred coal

Before Drying

After Drying

Coal slime is a by-product of coal washing, and cannot be easily utilized on a large scale due to its high levels of moisture content, high viscosity, high ash content, and low heat value properties. In recent years, the amount of coal slime has increased drastically due to the fast rise in the amount of coal washing across the world, which could potentially lead to significant energy waste and environmental pollution. Currently, the preferred means of utilizing coal slime is combustion as fuel for power generation; however, the high level of moisture content may act as a dominating obstacle hindering its wide application, and potentially endangering the stable operation of the boilers. Consequently, the drying process of coal slime before burning is essential to lowering the moisture content and improving the heat values so that the coal slime has wider application with respect to economic, social, and environmental considerations.

The coal slime value can only be fully reflected when it is dried. It increasingly exposed a lot of drawbacks to use ordinary drum dryer on coal slime. So the drying technology should be greatly developed to overcome these adverse characteristics.

Petroleum Petcoke is the co-product of several processes used in petroleum refining to upgrade “residuum”into gasoline and middle distillate-range fuels. Residuum (or resid) remains after refineries initially distill heavy crude oils. Petcoke is a black-colored solid composed primarily of carbon, and may contain limited amounts of elemental forms of sulfur, metals, and non-volatile inorganic compounds. The petroleum industry and federal regulators characterize petcoke as a “co-product” because it may have some commercial value as a boiler fuel and as a raw material in manufacturing. Refineries also produce petcoke as a by-product of catalysis, which refineries later consume as a fuel.

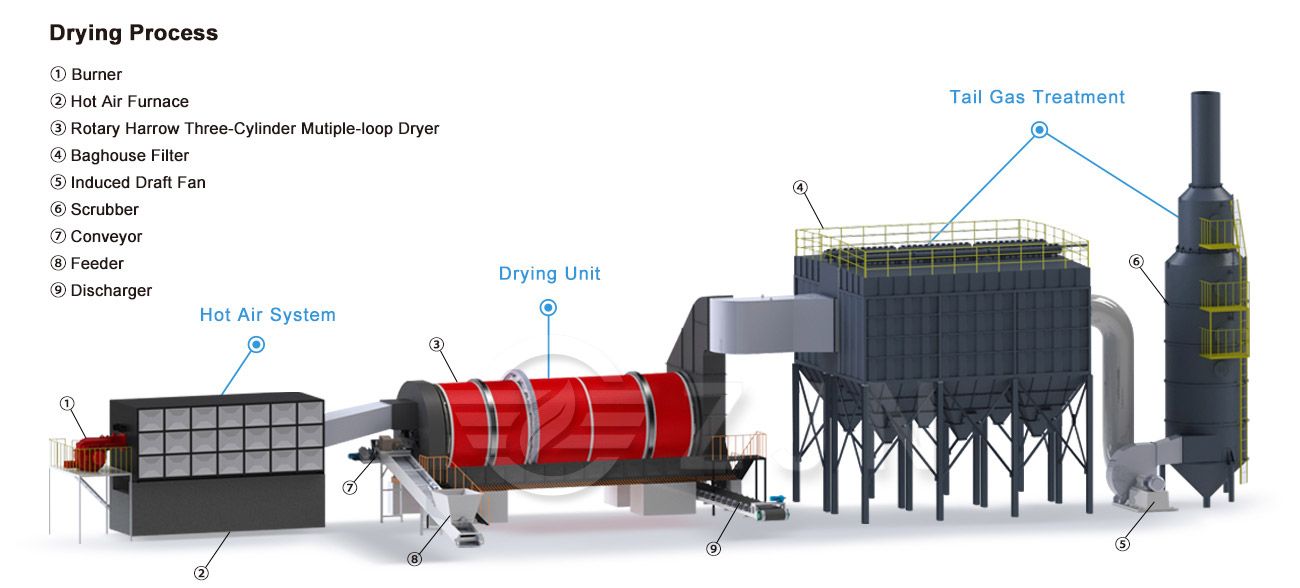

ZJN eventually developed a multi-loop hot air drum drying system specially for Coal Slime/Lignite/Coke/Peat Drying

It has primary crushing, dispersing, breaking up, anti-stick wall process, and composed of rotary harrow, w guide plate, gears, ring gear, tugs, torches, power device and automatic feeding and discharging devices. The heat source is provided by the hot air furnaces. Material Directly contact with hot air. The whole drying process runs under a closed and negative pressure state, ,which is safe and not easy to damage. Heat exchange is fast, the water evaporates quickly, and the temperature and the amount of coal slime are controlled, never blocking and sticking. The automation, industrialization, continuous working greatly improves the production and quality.

1. To be processed as briquette for industrial boilers or residents living;

2. As fuel for the foundry industry, to improve fuel efficiency, reduce production costs and increase economic benefits;

3. As brick factory additives, to improve the hardness and compressive strength of the brick;

4. As cement plant adding materials to improve the cement performance;

5. Some of the specific ingredients of slime can also be used as chemical raw materials.

The production line of dryer for mining, metallurgy and chemical industry generally includes: heating system, drying host, induced draft system, dust removal system, conveying device and control system, etc.

The dryer for mining, metallurgy and chemical industry can use natural gas, steam, biomass particles, fuel oil, coal, boiler exhaust and other heat sources for heating. It has a wide range of applications and is convenient for different users to choose.

We can design a scientific and reasonable drying scheme according to the characteristics of materials, output, drying degree, site size and other requirements, so as to meet the diversified drying needs of users.

The dryer of mining, metallurgy and chemical industry has large heat transfer area, long drying stroke and high storage capacity. In the dryer, there are not only vortex motion, but also a lot of reciprocating motion. The unique mechanical anti guide material technology enables the dryer to hold a large number of materials.

The hot air, materials, the guiding material system and anti guide material system in the dryer complement each other and interact with each other, forming the whole benign system. The whole drying process is harmonious and orderly, the heat energy is fully utilized, the output is greatly improved, and the effect of energy saving and consumption reduction is really achieved.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

It is suitable for drying slime, raw coal, clean coal, lignite, coke, blue carbon, pulverized coal, industrial salt, iron powder, gypsum, tailings, quartz powder, bentonite, sand and other materials.

Widely used in coal, chemical, mining and other industries.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. Negative pressure operation, good sealing and insulation effect, low heat loss, clean and sanitary site.

2. The equipment has variable speed transmission, stable operation and low failure rate.

3. The production process of the equipment is excellent, the quality is excellent, the technology is advanced and mature, and the production performance is stable and reliable.

4. The whole drying system is centralized control, high degree of automation, simple and convenient operation.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.