All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: all kinds of pulp

Before Drying

After Drying

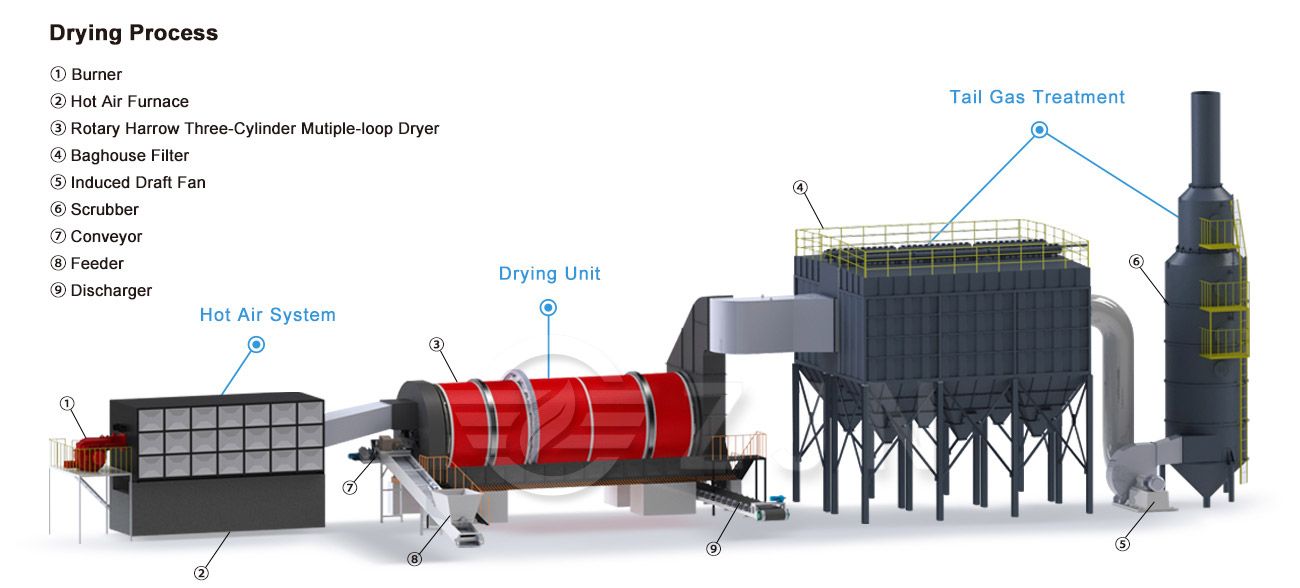

"Paper Pulp" is a kind of block material formed by soaking, removing impurities, smashing, pulping, filtering and dehydration of recycled cartons, book papers and newspapers. It is mainly composed of a variety of fibers with high water content. When the "Paper pulp" is dried to a certain extent, it is in a flocculent state that is easy to burn. At this time, if the temperature is too low, it will not meet the drying requirements, and if the temperature is too high, it will easily lead to fiber plasticization or even fire burning. Therefore, it is very difficult to dry, and temperature control is particularly important.

In the traditional single cylinder dryer, the material enters and exits directly in the equipment, and it operates in a single stage. The air volume and temperature can not be controlled accurately, and the water vapor travel in the equipment is too long. Because of the water absorption characteristics of the pulp, it is very easy to get wet at the end, and it is difficult to achieve the ideal drying effect.

The "three cylinders and multiple-loop grid" paper pulp dryer which is produced by ZJN company is based on the "single cylinder dryer", adopting the leading "three-stage and multiple-loop drying technology" in China at present, and after innovative design and transformation. The unique three cylinders design divides the material drying process into three stages. Then, according to the characteristics of the material and drying requirements, the air volume, wind speed, wind direction and heat are distributed freely and controlled independently; the water vapor is discharged at the end of each stage in time, greatly improving the drying efficiency.

In the drying practice, the drying parameters of "paper pulp" formed from different raw materials are also different. Only after accurate testing can accurate drying data be obtained. At present, many enterprises at home and abroad use the "three cylinders multiple-loop grid" paper pulp dryer produced by ZJN company to dry the "paper pulp", and the drying effect is very ideal.

The "three cylinder multi return network" paper pulp dryer includes a number of core concepts of ZJN (1 + 3 = 6" three sleeve mode, "3 × 6 = 36" W + s feeding design, "6-3 = 1" exhaust mode, and "3-step forward and 2-step backward" AC reciprocating drying technology), combined with the advanced "positive and negative lifting and guiding" system, when the pulp in the equipment "3-step backward 2-step" reciprocating transportation.At the same time, it is repeatedly thrown and raised to form multiple uniform "curtain", so as to ensure the full contact and fusion of hot air and pulp, increase the heat transfer area to five times of that of ordinary dryer, and make the pulp stroke more than six times of the designed length of the equipment. The whole equipment integrates, interacts and complements each other. The quantity and temperature of hot air in the first, second and third drying rooms are adjusted according to the fluctuation of pulp moisture content. The new design process of "high + high + high", "medium = medium", "low low low" is used to make the temperature and hot air always match the moisture of material. The pulp is always placed in the ideal drying environment. Low energy consumption, high efficiency, comprehensive economic benefit is three to four times of ordinary drying equipment.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

Pulp dryer is suitable for drying all kinds of pulp, and can be used in papermaking industry and waste paper recycling industry.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. The equipment adopts three cylinder drum structure, which greatly reduces the floor area of the equipment. At the same time, it can be assembled reasonably according to the actual land area of users.

2. Automatic operation, high degree of intelligence, low labor intensity, simple and convenient operation.

3. The technology is mature, the performance is stable and reliable, it can run 24 hours continuously, and the equipment failure rate is low.

4.The equipment has large capacity and high utilization rate of heat energy, which can save energy and production cost.

5.The whole equipment is tightly sealed and operated under negative pressure. There is no inflammable and explosive phenomenon in the production process.

6.It can not only save energy consumption, but also ensure the quality of finished products.

7.The quality of the dried product is even, and the state and size of the dried dregs can be adjusted according to the user's requirements, so as to facilitate the next use.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.