I believe that many users who don't know much about the dryer don't know how the electroplating sludge dryer works and what's the working principle? Many electroplating enterprise users ignore this point when purchasing dryer equipment, resulting in backward equipment technology, low efficiency, high energy consumption, and the cost of a large sludge dryer is not cheap, which causes some unnecessary losses. ZJN editor here reminds the users who are interested in purchasing the equipment, it is not too late to make a decision after understanding the working principle of the equipment.

There are many electroplating sludge drying equipment in the market. According to the principle of work, it can be divided into slurry blade, spray type, vibrating fluidized bed, rotary drum, disc type and so on. Here, take the current environmental friendly "Rotary harrow three cylinders multiple-loop" sludge dryer as an example to introduce its working principle.

The equipment adopts a "three sleeve" structure, that is, the main body of the dryer is nested by three concentric circles. One of the advantages of this design is that it can save energy, make full use of heat energy and reduce heat loss. When the dryer is working, usually the high humidity and high viscosity materials to be dried will be sent to the hopper by belt conveyor, bucket elevator and other devices, and then sent to the dryer barrel through the feeding device. At this time, the dryer is in a non-stop rotating state driven by the motor. After the wet material enters, it is first broken into small particles by the built-in "rotary rake crushing" device, and then it rolls continuously under the action of the board, repeating the process of lifting and scattering the centrifugal movement until the sludge particles are spread into a uniform material curtain and filled the whole drying space.

At this time, the dryer adopts the way of direct heat transfer to evaporate the moisture in the sludge, that is, the hot air or flue gas directly contacts with the sludge, and fully removes the internal water in the sludge by the way of forward flow and reverse flow to increase the drying efficiency. So what's forward flow and reverse flow? Forward flow is also known as parallel flow, that is, the hot air and materials have the same flow direction, which can quickly remove a large amount of water; reverse flow is the reverse flow of hot air and materials, which increases the degree of disorder, and can effectively remove the deeper water in the sludge. Using this principle, the whole drying process is divided into three stages: forward flow, reverse flow and reciprocating drying, which guarantees the drying quality and speed.

In the reciprocating drying stage, under the action of hot air and special material plate, the wet sludge moves back and forth and slowly, increasing its drying time in the equipment, and the dry sludge moves fast and first. After drying, it is automatically discharged from the discharge port, thus improving the uniformity of drying and ensuring the quality of products.

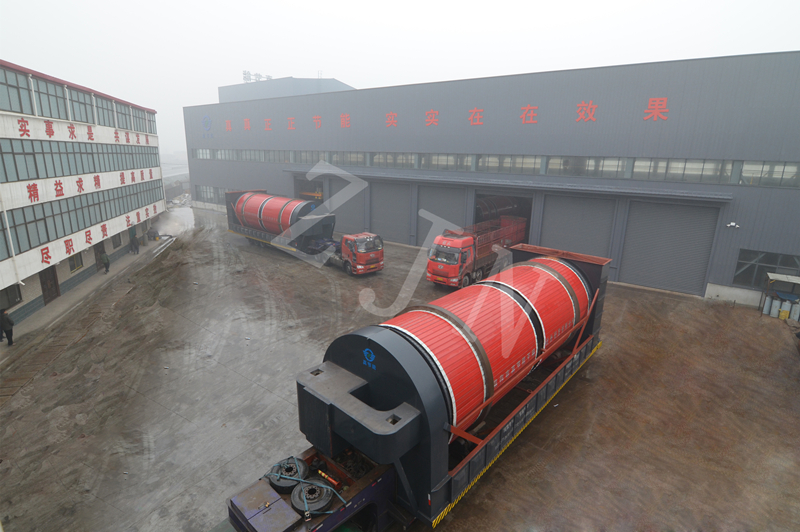

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.