The sludge dryer can deeply dry and dehydrate the sludge with high moisture and high viscosity, realize the killing of organic compounds in the sludge, and reduce the environment for bacteria breeding. With the continuous improvement and upgrading of sludge drying technology, the disposal method of sludge is also developing, and the reliability, stability and sustainability are guaranteed. In this era of various drying equipment came into being, how to choose a sludge dryer with mature technology, convenient operation and appropriate price is the issue to be discussed in this paper. Next, through the analysis and comparison of the mainstream devices in the market, the advantages and disadvantages of these devices can be deeply understood by users who need to buy them.

1. Fluidized bed dryer

The equipment adopts the compound heating mode of direct heating and indirect heating to dry the sludge. Due to the different arrangement of tube bundles inside the fluidized bed, these internals not only play the role of crushing sludge, but also have the function of heat conduction. After the sludge is dried, it will be carried out with hot air, and the tail gas can be discharged only after purification by waste gas treatment equipment.

The equipment has the advantages of large processing capacity and fast drying speed. However, due to the collision and contact between the hollow internals and sludge for a long time, it is easy to damage and increase the maintenance cost.

2. Hollow paddle sludge dryer

The equipment adopts indirect heating method. There are 2 ~ 4 hollow blades in the shell with jacket. In the drying process, the hot air flows through the hollow blades and the shell. Through the heater wall, the sludge on the other side is heated, and the water in the sludge is evaporated. The hollow paddle also has the function of stirring sludge. The advantages of this process are simple waste gas collection, strong cleanliness and low equipment operation cost. However, due to the adoption of indirect heating process, the heat loss is relatively large, and the drying efficiency is not as good as that of direct heating. Moreover, due to the long drying time, the treatment capacity is not large, so it is suitable for enterprises with small sludge treatment capacity.

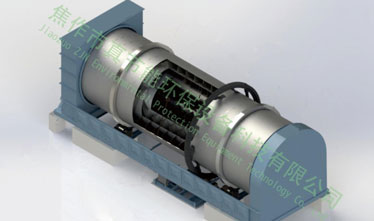

3. Three stage multi loop sludge dryer

The cylinder structure of the equipment is very special. The appearance is a cylinder placed horizontally and slightly inclined. The main body is composed of three concentric cylinders, with a "rotary rake crushing" breaking device and a scientifically distributed lifting system. In the drying process, the sludge and hot air move in the order of inner cylinder, middle cylinder and outer cylinder through direct contact. Through the mutual cooperation of dispersing device and lifting system, the heating area of sludge is increased and the movement state of sludge particles is changed, which effectively avoids the problem of high humidity and high viscosity sludge sticking. The three-layer sleeve structure can greatly extend the sludge drying stroke, reduce the area occupied by the cylinder and save the plant resources.

The three-stage multi loop sludge dryer can adapt to the drying of high moisture and high viscosity materials with different moisture content. The daily treatment capacity of a single equipment can reach 100 tons, with high drying efficiency and low energy consumption.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.