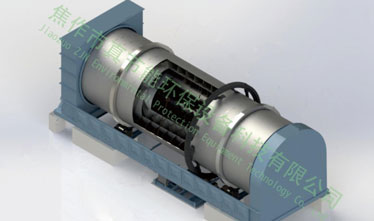

Multi return environmental protection sludge dryer, also known as three sleeve sludge dryer, is developed on the basis of single drum dryer through structure optimization and technical upgrading. At present, it is mainly used in sewage treatment, electroplating, leather, chemical industry, pharmaceutical, papermaking, printing and dyeing, metal treatment and other industries. It is a special equipment for drying high humidity and high viscosity sludge. ZJN three-stage multi loop environmental protection sludge dryer can meet the characteristics of materials in different industries and the moisture requirements after drying. The required moisture content can be achieved by one drying, effectively reducing the moisture in high humidity and high viscosity sludge, with good capacity reduction and reduction effect, which is very suitable for large amount of sludge drying operation. Next, we will introduce the working principle and performance characteristics of multi return environmental protection sludge dryer.

Working principle of environmental protection sludge dryer

A complete set of environmental protection sludge drying machine is usually composed of the following equipment or components: heating equipment, feeding system, feeder, drying host, discharge system, vibration grading screen, induced draft fan, dust removal equipment, PLC automatic control cabinet, etc. The wet sludge will be fed into the feeding hopper through the feeding system, and then enter the drum from the higher end of the drying machine. Since the drum of the dryer will rotate continuously during operation, the sludge in the drum will also be brought to the high place with the rotation and then fall down. The special three-layer sleeve structure, combined with the "rotary rake crushing" breaking device set in the cylinder and the interlaced distribution of the lifting plate, greatly increases the contact area between the sludge particles and the hot air flow, improves the drying rate and promotes the material to move forward.

Performance characteristics of environmental protection sludge dryer

1. Environmental protection

Steam, natural gas, biomass fuel and other clean heat sources can be selected, and combined with multi-stage dust removal equipment, such as cyclone dust collector, bag filter, desulfurization scrubber, etc., the waste gas treatment scheme can be designed and customized according to different conditions of users. The whole process ensures an environment-friendly, green and clean working environment, and the waste gas can meet or exceed the local environmental protection standards after purification.

2. Energy saving

The three-layer sleeve type energy-saving technology has the advantages of good heat preservation effect, small heat loss and low energy consumption. The whole system adopts the fully sealed design and is equipped with wear-resistant and high-temperature resistant stainless steel cylinder wall.

3. High yield

The daily production capacity of a single equipment can reach 100 tons. The equipment has simple structure, flexible operation, low failure rate, long-term stable operation and simple maintenance.

4. It is widely used

The moisture content of dried sludge is greatly reduced, which can be used in environmental protection building materials, land use, cement additives, calorific value utilization and other fields.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.