The working mechanism of three drum pulp sludge drying equipment is to realize sludge drying by convection of hot gas. The equipment relies on a special thermal energy generating device to transfer the generated heat in the form of hot gas to the surface of sludge in contact with it, and then transfer it to the sludge interior through the surface, so as to realize the evaporation of water seal on the surface of sludge rapidly. On the other hand, a special breaking device and a guide plate are set inside the barrel of the equipment. In the process of drying, the sludge can be broken and stirred continuously, which can not only increase the surface area of sludge, but also accelerate the full contact between sludge and hot air, which can not only improve the utilization rate of heat energy, but also improve the production efficiency.

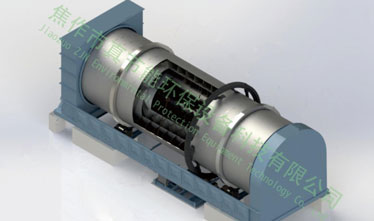

The main structure of three drum pulp sludge drying equipment is composed of support structure, transmission structure, cylinder structure, feed structure, discharge structure and so on. The cylinder structure mainly consists of three cylinders with different diameters, which are outer cylinder, inner cylinder and middle cylinder. When the dryer starts to start, the sludge first enters the inner cylinder through the feed tank, and then under the action of the guiding material, it continuously spreads around and turns longitudinally to fully exchange heat with the high-temperature heat transfer medium in the inner cylinder, and then passes through the middle cylinder and the outer cylinder successively through the circulation mode, and the sludge meeting the drying requirements is sent out through the discharge device. However, the water vapor produced by drying flows out from the end of the cylinder.

Compared with the traditional single drum drying equipment, the length of the three drum pulp sludge drying equipment is one third of that of the single drum; secondly, the three cylinder structure can disperse the sludge in the three cylinders, increase the contact area between the sludge and heat medium, and its treatment capacity is three times of that of the traditional single drum drying equipment; Third, the time of heat exchange between the three cylinders of materials and hot gas is long, and the energy consumption is low; fourth, the application range of three cylinder drying is wide, and the use range of heat source is wide.

At present, there are many manufacturers of three drum pulp sludge drying equipment on the market, and their prices are also varied. And Jiaozuo ZJN is one of them. Jiaozuo ZJN has more than 30 years of rich equipment processing and management experience, constantly explore and innovate the drying equipment, constantly upgrade and optimize the equipment, the produced equipment, whether in terms of quality or after-sales, are guaranteed, the price is reasonable, welcome the majority of users to buy at ease, we will have professional technical personnel to provide you with full service! If you have other questions about the equipment, you can also call true energy saving, we 24 hours online service for you!

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.