At present, there are various types of sludge drying equipment on the market, and the technology used is also different. From the perspective of heat transfer mode, the heat transfer mode of high humidity and high viscosity sludge drying equipment can be divided into forward heat transfer and reverse heat transfer, each of which has its own characteristics. In addition to the price factors, users also pay close attention to the performance, technical process, drying capacity, processing capacity and energy consumption of the equipment, so as to realize high-quality material drying with lower cost. So for the sludge with high humidity and high viscosity, which heat transfer method is better? This is also the problem to be discussed next.

Which heat transfer mode is better for sludge drying equipment

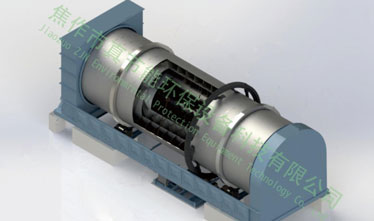

After entering the cylinder of sludge drying equipment, the sludge with high humidity and viscosity will be broken into fine particles through the dispersing device, and will be lifted and scattered continuously under the action of the lifting plate. At this time, the sludge and the hot air entering the cylinder will be in close contact, and the heat transfer area will be greatly increased. In the process of drying materials, according to the different heat transfer modes of materials and hot air, they can be divided into two types: forward heat transfer and reverse heat transfer.

The forward heat transfer is that the high temperature hot air flow and the wet material enter into the drum from the same side of the cylinder body of the sludge drying equipment, and gradually move to the other end (discharge end) with the rotation of the cylinder, and the heat is transferred continuously in this process. In the beginning of drying, the temperature difference between the wet material and the hot air is large. At this time, the material can be fully contacted with the high-temperature hot air flow by adopting the forward flow drying, so that the moisture on the surface of the wet material will evaporate rapidly under the high temperature, which greatly reduces the moisture and viscosity of the sludge, thus effectively improving the whole process Efficiency of drying operation. However, with the continuous advance of the forward heat transfer process, the temperature in the cylinder decreases due to the material heating and heat loss.

The reverse heat transfer method is that the hot air and materials enter the cylinder from both ends of the sludge drying equipment, and with the continuous rotation of the cylinder, the wet material gradually contacts with the high-temperature air flow coming from the face and realizes the heat exchange process. In this way, the temperature in the cylinder is in a relatively stable state, which can effectively guarantee the drying quality of materials and filter out part of the dust in the materials. But the reverse heat transfer drying speed is slow, for the high humidity and high viscosity materials, it is inevitable that the phenomenon of adhesion and agglomeration will occur.

However, in the actual production of sludge drying equipment, users can determine which heat transfer mode to use according to the actual production line conditions, and can also choose the equipment combining forward and reverse heat transfer. Only those suitable for themselves are good.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.