Municipal sludge is often treated as waste, but due to the characteristics of high water content, high viscosity and easy to decay, especially in summer, it is easy to rot and emit odor. If it is not treated in time, it will not pollute the surrounding environment. On the other hand, with the development of economy, the output of municipal sludge is increasing year by year, which also brings difficulties to the treatment and disposal of sludge. At present, multi return municipal sludge dryer is an important equipment for dehydration and drying of high moisture and high viscosity sludge, which is widely used in various industries.

Working principle of multi return municipal sludge dryer

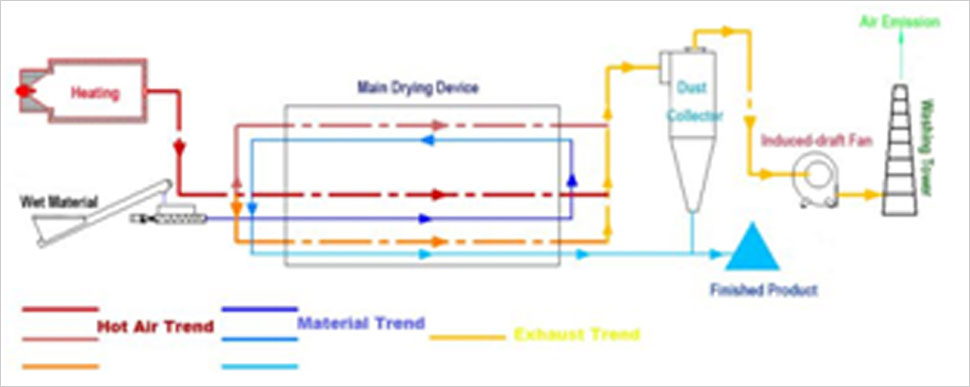

The wet sludge to be treated is transported to the hopper of municipal sludge dryer by conveyor (belt conveyor or bucket elevator), and the material is sent into the dryer barrel through the feeding device of hopper. In general, the main body of the municipal sludge dryer is slightly inclined to the horizontal line, which can facilitate the smooth entry of materials into the cylinder.

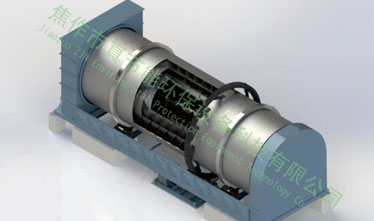

The cylinder of municipal sludge dryer is the main place for heat and mass transfer of materials and hot air, which is composed of three nested rollers. After the wet material enters the cylinder, it will be broken into fine particles under the action of the dispersing device, and then it will be lifted and scattered continuously under the action of the lifting plate, and slowly move forward to the other end of the cylinder. In this process, the moisture in the material will continue to evaporate and dry under the action of high temperature hot gas, so as to achieve the effect of dehydration. The finished product after dehydration is discharged through the discharge end.

Installation guide for multi return municipal sludge dryer

There are many parts related to the installation of sludge dryer according to its own characteristics.

1. Before installing the multi return municipal sludge dryer, check whether the parts are damaged or missing. If there is any problem with the parts, contact the manufacturer for replacement or repair in time to ensure that the parts received are correct before installation.

2. Before the installation of the equipment, the technicians need to understand the equipment installation and process requirements, be familiar with the drawings, determine the installation sequence and method, and ensure the accuracy of the installation process.

3. For parts and key parts, pre inspection and pre assembly shall be carried out to avoid rework during installation and ensure installation progress and quality.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.