Sludge is the waste sediment produced in the process of sewage treatment, which has the characteristics of high humidity, high viscosity and complex composition. With the rise of industrial economy, the amount of sludge to be treated in our country every year is amazing. On the one hand, these characteristics have a serious impact on the surrounding environment, on the other hand, they make a lot of achievements in building materials, metallurgy, environmental protection and other fields. Therefore, sludge recycling is of great significance to both economy and environment. Sludge drying equipment is developed according to the characteristics of sludge, which can help mass treatment and recycling of sludge.

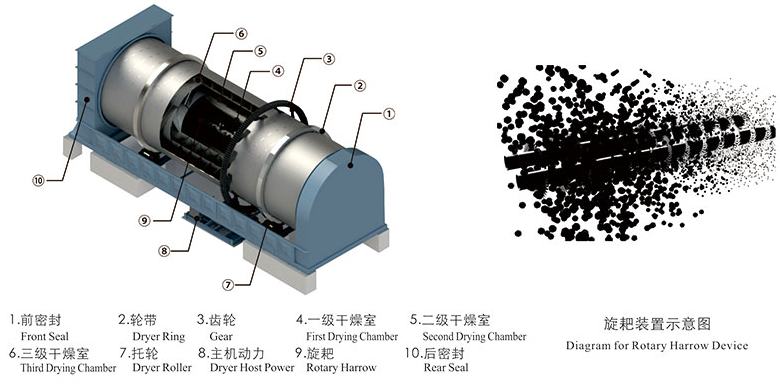

The sludge drying equipment adopts three-layer sleeve process, the structure in the cylinder is upgraded, and a variety of drying processes such as forward flow, counter flow and reciprocating drying are adopted, and the dispersing device and lifting device in the cylinder are upgraded and improved. After the sludge is sent into the cylinder through the feeding device, the dispersed sludge is fully contacted with the high-temperature hot air and heat exchanged to evaporate a large amount of water. In the high-speed cylinder, the sludge particles are constantly thrown up and scattered, forming a uniform and thin material curtain on the cross section, which greatly reduces the dead angle of the sludge adhering to the cylinder and the phenomenon of material blocking, and effectively solves the problem of high humidity fouling It is difficult to dry mud. It can be dried quickly by layer by layer "stripping" and deep drying. A qualified sludge drying equipment should not only have scientific and reasonable process flow, but also pay more attention to equipment material, performance, operation cost and after-sales service.

Features of sludge drying equipment:

1. From the perspective of structure

Compared with the single cylinder equipment, the length of the equipment is greatly reduced, the structure is more compact, the floor area is small, and the civil engineering investment is less

2. From the material point of view

The cylinder is made of wear-resistant and durable stainless steel, which has a longer service life.

3. In terms of performance

The equipment has stable performance, can work continuously for a long time, stable operation, safe and reliable, good sealing and heat preservation, no dust spillover, and clean working environment.

4. Energy saving effect

The special three cylinder nested design makes the hot air flow in the cylinder more overlapped and fully utilized, and the heat loss is greatly reduced. The sludge drying equipment can also cooperate with the energy-saving technology of "using boiler tail gas" to further reduce the use cost of fuel.

5. Environmental protection effect.

According to the regional environmental protection standards, the multi-stage dust removal device is designed to ensure the waste gas treatment up to the standard.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.