Industrial sludge dryer is a kind of large-scale mechanical equipment specially designed for drying and dewatering of high humidity and high viscosity industrial sludge (such as printing and dyeing sludge, electroplating sludge, leather sludge, chemical plant sludge, etc.). As one of the widely used sludge treatment equipment, industrial sludge dryer can dry the high wet sticky sludge to the required moisture content level at one time. It has the advantages of high thermal efficiency, strong production capacity and good effect of reducing volume and weight. It is widely used in various chemical industries. Many users want to know the working principle of the equipment and other related knowledge before purchasing the industrial sludge dryer. In order to better use the dryer equipment, the following small series will introduce them one by one.

Working principle of industrial sludge dryer

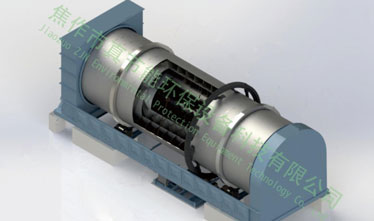

The whole set of industrial sludge dryer production line is mainly composed of heating equipment, conveyor, feeder, dryer, discharging machine, induced draft fan, dust removal equipment, PLC automatic control system and other components. Users can choose many heat sources, such as natural gas, steam, coal, fuel oil, biomass fuel, boiler waste heat, etc. users can choose according to their own drying needs and the convenience of obtaining fuel. The induced draft fan ensures that the equipment can operate under negative pressure with strong reliability; the dust removal equipment ensures the waste gas treatment, and the waste gas can reach or be higher than the local environmental protection standard after being purified by the dust removal equipment; various parameters of the equipment can be flexibly adjusted and controlled by the automatic control system, so that the materials are always in a suitable dry environment.

The industrial sludge dryer is the main place for heat and mass transfer between wet materials and hot air. The wet sludge enters the dryer barrel through the feeding device, and through the "rotary rake crushing" device, the wet materials are continuously dispersed and rolled, showing a "boiling" state. Under the joint action of the guiding and lifting systems, a uniform and complete material curtain is formed. At the same time, the hot air passes through and mixes with the materials to accelerate the drying speed. After the drying, the finished products are discharged from the outlet.

Characteristics of industrial sludge dryer

1. The drying technology is mature, and the drying of high humidity and high viscosity sludge is more targeted and professional, which effectively improves the quality and quality of finished products.

2. The cylinder body and other devices are made of wear-resistant and high-temperature resistant stainless steel, with long service life.

3. The daily output can reach more than 100 tons and the treatment capacity is large, which can meet the production requirements of large and medium-sized enterprises for high-yield and high-speed rate.

4. The stability and heat preservation performance of the equipment are relatively high, and there will be no material blockage, equipment vibration and other failures. The three-layer sleeve structure can make full use of the heat resources and reduce the heat loss.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.