Due to the enhancement of national economic strength and the improvement of national environmental protection awareness, sludge and sewage treatment has become a serious problem for every sludge treatment and disposal enterprise. At present, the three cylinder sludge drying equipment on the market is more energy-saving and environmental friendly than the traditional dryer. By setting waste gas treatment equipment in the production line, the waste gas can be effectively prevented from being directly discharged into the atmosphere to cause pollution, which can not only protect the surrounding environment, but also protect the health of the operators, and effectively reduce air pollution. What is the technological process of sludge drying equipment?

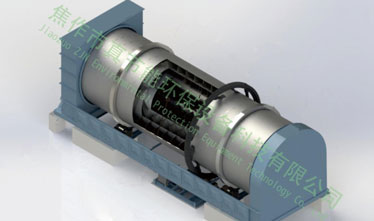

The sludge drying equipment consists of three layers of rollers. Firstly, hot air and wet materials enter the sludge drying equipment from the same side, and a large amount of water is quickly evaporated by high temperature hot air. The whole drying process can be divided into three stages, using downstream, countercurrent, reciprocating drying mode, high drying efficiency, small heat loss. Wet sludge and hot air enter the cylinder from the same side, and in the downstream drying stage, they move in the same direction, and a large amount of water vapor is evaporated due to the large temperature difference. In the counter current drying stage, the sludge and hot air move in opposite directions, which promotes the rapid evaporation of water in the sludge. The sludge that has not been dried will be discharged from the discharge port after the moisture content reaches the requirement.

For the sludge with high humidity and high viscosity, how does the sludge drying equipment deal with it? In fact, the "rotary rake crushing" dispersing device and the combined lifting device set in the cylinder effectively solve the difficulties of easy agglomeration and wall sticking when drying the sludge with high humidity and high viscosity. The wet sludge and hot air in the cylinder can fully disperse the viscous material under the action of the dispersing device, which greatly improves the contact area between the material and the hot medium and is conducive to the drying process. Special lifting device can effectively avoid the phenomenon of material sticking to the wall. The equipment is specially designed for drying high humidity and high viscosity sludge, so that the sludge particles are continuously raised and scattered, forming a uniform thin material curtain on the cross section of the cylinder, greatly increasing the contact area between wet sludge and hot air, and improving the drying efficiency.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.