There are many kinds of sludge drying equipment in the drying market. Users need to choose the appropriate equipment according to the characteristics of the dried materials, the requirements of drying degree and the requirements of output. Due to the different drying requirements of different users, the drying requirements of materials are also different, which directly affects the selection of sludge drying equipment. What are our common sludge drying equipment?

1. Plate and frame sludge dewatering and drying equipment

The sludge pumped by the high pressure pump is squeezed to discharge water from the filter cloth. The equipment has the advantages of low investment price, fast drying speed and simple structure. But it is also easy to block the material, so it needs to be controlled well when feeding. Moreover, due to the need of high-pressure pump for equipment operation, it is not suitable for sludge dewatering with high humidity and viscosity, so it is difficult to realize continuous automatic operation. The moisture content of dewatered sludge is still very high, which needs further processing and drying.

2. Belt type sludge dewatering machine

Depending on the tension of the filter belt, the squeezing force is formed on the sludge layer to squeeze out the water in the sludge layer, so as to realize sludge dewatering. But when the material is too much, it is easy to jam or extrude from both sides. The equipment has the advantages of low price, less investment and small floor area. But it also has some problems, such as low treatment capacity, high moisture content of sludge after dewatering, peculiar smell and so on.

3. Screw press sludge drying equipment

During the operation of the equipment, the volume between the screw blades in the drum is gradually reduced, and the sludge is gradually compressed. Through the compression principle, the purpose of solid-liquid separation in sludge is achieved.

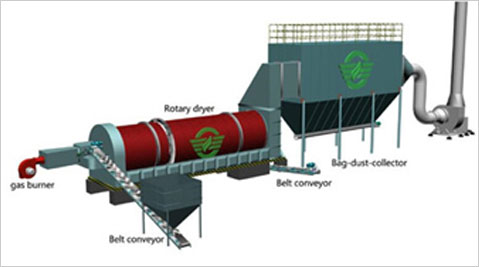

4. Multi return sludge drying equipment

The multi return sludge drying equipment adopts the principle of heat transfer between high temperature hot air and wet material to heat the sludge and evaporate the water. As the main body of the equipment adopts a three-layer sleeve structure, the length of the equipment is greatly reduced, and the installation position of the equipment can be arranged according to the site environment, so as to reduce the floor area and infrastructure investment. The overall heat utilization rate of the equipment is high and the heat loss is small. Special "rotary harrow crushing" breaking device and material lifting system are set in the cylinder. The broken material and hot air roll, lift and mix continuously, greatly increasing the contact area. High degree of automation, long-term continuous operation, good sealing performance, large capacity, suitable for drying high humidity and high viscosity materials.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.