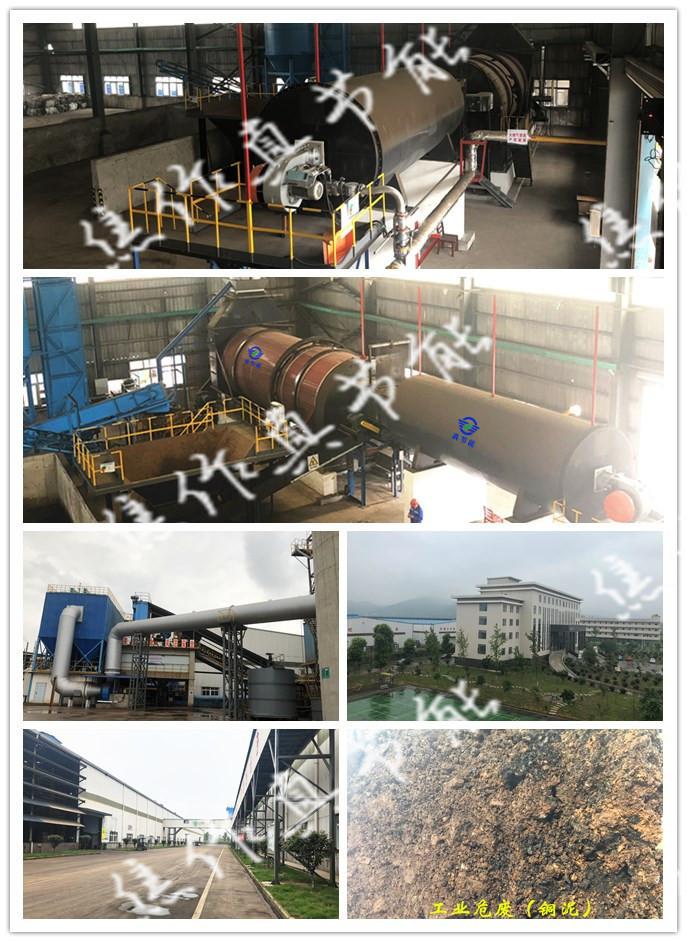

sing municipal sludge low-temperature dryer to dewater and dry high wet sludge is an important part of sludge treatment and resource utilization. More and more people look at the business opportunities and begin to introduce municipal sludge low-temperature dryer equipment. In the dry market goods are available in all varieties. They are paddle, drum type, multi return, spray type and so on. However, due to the characteristics of high water content, high viscosity and difficult treatment of municipal sludge, the phenomenon of wall sticking and agglomeration is easy to appear in the drying equipment cylinder in actual operation. Once the problem of sticking to the wall occurs, it will not only reduce the production efficiency of the equipment and the drying quality of the property, but also affect the service life of the equipment for a long time. Therefore, friends who encounter the problem of sticking to the wall must find out the reason and solve it in time.

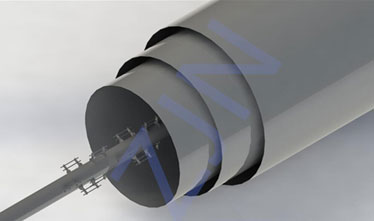

1. Unreasonable layout of internal structure

In general, there are dispersing devices and lifting devices inside the municipal sludge low-temperature dryer. If the internal structure design is unreasonable or the structure is too simple, it will cause problems such as long drying time and uneven drying of materials, and it is more likely that the materials stick to the drum and cannot be dried together. After the improvement of the internal structure of the cylinder, the dispersing device can quickly break the wet materials into bulk, and make the dense lifting plates in the cylinder continuously lift and scatter the materials, forming a uniform material curtain on the cross section of the cylinder, thus strengthening the heat and mass transfer process. In this way, it can effectively reduce the sticking problem of municipal sludge low-temperature dryer.

2. Change feed moisture content

The reason why sludge is easy to adhere and agglomerate is due to the characteristics of high water content and high viscosity. If the water content of some materials can be reduced during feeding, the phenomenon of sludge sticking to the wall during drying will be greatly alleviated. At present, many users will carry out pretreatment before drying for high humidity sticky materials. Mechanical dehydration can reduce part of the moisture content of materials, which helps to solve the problem of equipment sticking to the wall.

3. Change material movement state

In the drying process of municipal sludge low-temperature dryer, the sludge can be continuously activated, so as to avoid the sludge losing its "vitality" sticking to the dead corner of the cylinder wall or forming a mass. After the sludge is broken by the dispersing device, it is affected by its own gravity in the rotation of the cylinder, and the continuous lifting and falling of the plate, which makes the material reciprocating in high speed and reduces the possibility of adhesion and agglomeration.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.