Stainless steel sludge dryer is mainly made of wear-resistant and high temperature resistant stainless steel material, which is the main equipment of sludge drying production line. In addition, there are heating equipment, dust removal equipment, induced draft fan, feeding and discharging device, etc. As a commonly used heating equipment, the selection of hot air stove's heat source affects the operation cost of the equipment. Therefore, the selection of heat source must be based on the comprehensive consideration of local conditions, convenient access and drying quality. The existence of induced draft fan enables the dryer to operate under negative pressure and discharge the waste gas in the cylinder. The discharged waste gas will be discharged into the air after being purified by the bag filter.

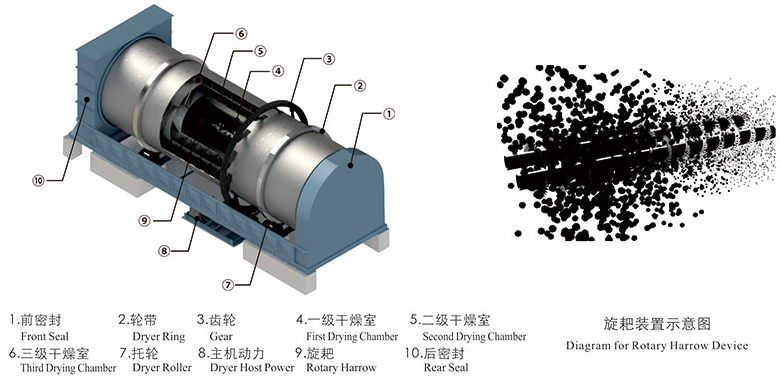

The production capacity of large-scale stainless steel sludge dryer can reach more than 100 tons every day. The new equipment developed by ZJN adopts the three-stage multi loop sludge dryer patent (Patent No. 2014305580432) technology. After wet sludge is fed into the cylinder through conveying device and feeding device, the following drying steps are generally required.

1. Drying along the flow, rapid dehydration

Wet sludge and hot air enter the cylinder from the same end of the dryer. The dispersing device of the equipment in the cylinder and the combined lifting device break, disperse, lift and scatter the large wet sludge continuously, which greatly increases the contact area between the material and hot air. The two move in the same direction. Due to the large temperature difference, the wet sludge evaporates a lot of water after being heated.

2. The internal water of sludge is removed by counter current drying.

The hot air runs opposite to the material, which makes full use of the heat energy emitted by the inner cylinder and effectively removes the water inside the sludge. Moreover, the dust in the hot air is filtered by the wet material, which reduces the dust content and reduces the difficulty of tail gas treatment.

3. Reciprocating feeding, uniform drying stage.

The materials that are not completely dried move forward and backward in the cylinder, and the completely dried materials are discharged from the outlet to ensure the quality and effect of drying.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.