Sludge drying equipment plays an important role in dehydration and drying of high humidity and high viscosity materials. It is the basic premise to ensure the smooth drying operation to install and maintain the sludge drying equipment. It is necessary to install the sludge drying equipment correctly and maintain the equipment in daily life, and operate the equipment scientifically and reasonably, which can make the sludge drying equipment play a good performance advantage in the operation process. The operator needs technical training before taking the post, so as to ensure the drying effect of sludge drying equipment.

Precautions during installation of sludge drying equipment:

1. Before installation of sludge drying equipment, for key parts and key parts of equipment, relevant matters such as installation inspection plan, quality requirements, technical standards, deviation range, tools and measuring tools required for installation shall be prepared. The advantage is to provide reliable theoretical support for the installation of sludge drying equipment, and also provide the basis for the future rectification and maintenance. When installing sludge drying equipment, it can be well-known, avoid installation errors, rework and other situations, and ensure the orderly installation process.

2. When installing sludge drying equipment, the work of backing plate should be done well. Pay attention to the installation position when installing the backing plate, and what should be paid attention to when installing and maintaining the sludge drying equipment as far as possible

In the position of near load, the uneven force of the backing plate shall be avoided. During the installation, the number and position of each group of backing plates shall meet the requirements to ensure that the placement is orderly and in contact with the place.

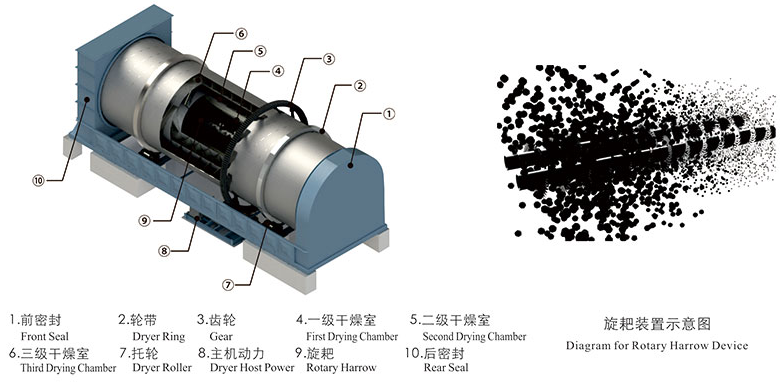

3. When installing the drum of sludge drying equipment, keep the cylinder horizontal and slightly inclined, the main body shall be placed stably, and the contact with the foundation below shall be dense, and there shall be no angular shaking phenomenon. When installing pipes and other devices, pay attention to tight sealing at the joint, and add sealing devices at both ends of equipment to avoid air leakage during equipment operation.

Precautions during maintenance of sludge drying equipment:

1. In order to prevent overheating of equipment, the heating temperature of equipment should be controlled well, the temperature range specified by equipment operation should be avoided, equipment deformation should be prevented and normal operation of sludge drying equipment shall be ensured.

2. Ensure lubrication in place, regularly check whether all parts of gear and bearing of equipment need lubrication, and the firmness of fasteners and bolts to prevent looseness or damage during equipment operation.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.