1. Boiler waste heat utilization technology

Generally, there are many kinds of heat sources for sludge drying equipment, such as natural gas, steam, biomass fuel, etc. The boiler waste heat sludge drying equipment mainly uses the boiler waste heat as the heat source, makes use of the waste heat resources owned by the enterprise itself, and turns waste into treasure. Through scientific drying technology design and equipment configuration, on the basis of meeting the drying needs of users for output, water content and so on, it greatly reduces the consumption of heat energy. Due to the energy-saving design, it has become more and more sludge treatment places The choice of enterprises. However, it should be noted that the use of boiler waste heat utilization technology requires enterprises to have boiler resources to use.

2. Low temperature drying technology

Compared with high-temperature drying technology, low-temperature drying technology is a new technology to realize sludge drying by increasing air volume at relatively low temperature. "Low temperature" means that the temperature of the heat source is not high, which can greatly reduce the fuel consumption of the heat source, thus reducing the operation cost of the equipment in the process of operation. Moreover, the low-temperature drying technology can avoid the problem of toxic and harmful gases in the process of high-temperature drying, and indirectly reduce the difficulty of tail gas treatment.

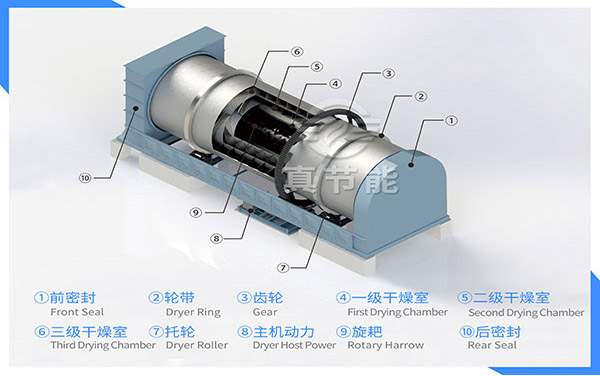

3. Three stage multi return drying technology

Three cylinder sets with different diameters are used to greatly extend the heating time of sludge in the dryer cylinder. The "rotary harrow crushing" device can quickly crack and separate the sludge into a "boiling suspension" state, greatly improving the dynamic and static contact area between sludge and hot air, making the sludge into non stick, non stick and non blocking loose particles, forming more uniform and more stable under the action of combined lifting plate The thin material curtain improves the drying efficiency and reduces the drying energy consumption.

4. AC reciprocating feeding technology

The sludge moves in three steps and two steps backward in the dryer drum, and the dry one goes first and the wet one goes slowly. After reaching the drying requirements, the material will be discharged automatically.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.