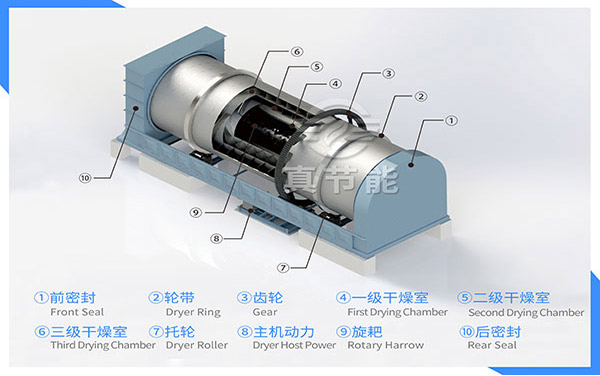

1. Special structure of three return sludge drying equipment

Compared with the traditional single drum sludge drying equipment, the main body of the three-way sludge drying equipment is made up of three layers of rollers nested each other, which greatly extends the drying stroke of materials and hot air, and effectively solves the problem that the single drum equipment is too long and covers a large area. The reduction of volume reduces the heat loss of the three pass sludge drying equipment when processing materials, which is not only convenient for installation and disassembly, but also saves a large part of the site capital investment cost for customers.

2. Three pass sludge drying equipment can process materials faster

Although the volume is smaller, the three pass sludge drying equipment can process materials faster. Due to the setting of crushing device, lifting plate and guide plate device with different angles and spacing in the cylinder, large pieces of materials will be scattered and broken after entering the cylinder, and continuously raised and dropped, increasing the contact area between materials and hot air, which can dry high humidity and high viscosity sludge more quickly.

3. The thermal insulation performance of three return sludge drying equipment is better

Compared with the single cylinder equipment, due to the special three cylinder structure, the inner cylinder and the middle cylinder are surrounded by the outer cylinder, thus forming a self insulation system. The heat emitted from the surface of the inner cylinder and the middle cylinder is fully utilized to strengthen the heat exchange effect, and the outer cylinder is at the low temperature end of the hot air flow, so the heat dissipation area and heat loss of the cylinder are greatly reduced It's too low.

4. The utilization rate of heat energy is higher when the three pass sludge drying equipment is used to treat materials

The three pass sludge drying equipment can make full use of heat energy, reduce heat loss, increase heat exchange area, and make water in sludge evaporate rapidly, so as to effectively improve the utilization rate of heat energy, reduce energy consumption and save the operation cost of the equipment. At the same time, it further reduces the pollution of waste heat to the environment. The waste gas treatment equipment in the drying production line purifies the waste gas containing dust and then discharges it into the atmosphere, which realizes the functions of energy saving, emission reduction and low-carbon environmental protection. Therefore, more and more users choose three return sludge drying equipment to deal with high humidity, high viscosity and mass drying operation.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.