Electroplating sludge drying equipment is a common equipment in drying industry. When users choose electroplating sludge drying equipment, they usually need to configure and design appropriate electroplating sludge drying equipment system according to the properties of materials and the requirements for output and drying effect. Meanwhile, the material and process type of equipment should be paid attention to so as to ensure the drying efficiency better And quality, for the enterprise to bring greater profits. The common structure of electroplating sludge drying equipment on the market is as follows: heating equipment, electroplating sludge drying equipment, dispersal device, lifting plate device, support device, conveying device, waste gas treatment equipment, etc.

1. Heating equipment

The heating equipment transmits heat energy to electroplating sludge drying equipment through burning fuel. The user can choose natural gas, biomass fuel, steam, boiler waste heat, fuel and other fuels as heat sources. The range of options is very wide. When selecting fuel, it can be determined by comprehensive consideration from the following aspects: convenience, fuel heat value, economy and environmental protection.

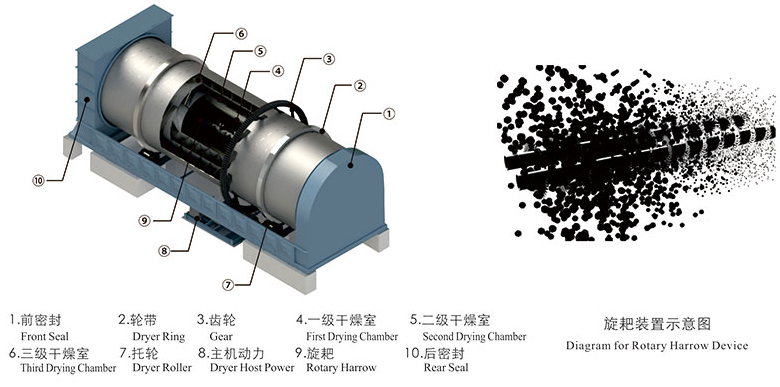

2. Electroplating sludge drying equipment

The barrel of electroplating sludge drying equipment is composed of three layers of rollers nested with each other, and the material is mostly stainless steel. The manufacturer will customize the appropriate equipment model and size for the user according to the characteristics of materials processed by different users, the requirements of production, the requirements of drying degree, etc. Generally speaking, the three tube electroplating sludge drying equipment covers less area, large drying output and high thermal energy utilization rate, and is widely used in various industries. In order to prevent the pouring, the material retaining ring and guide plate are installed at the feeding end of the dryer cylinder.

3. Breaking device and lifting plate device

The dispersal device and the lifting plate device are important parts in the drum of the electroplating sludge drying equipment. They can greatly increase the contact area between the material and the high temperature flue gas and improve the heat exchange capacity. Generally, the material entering the cylinder can be broken into scattered shape by the dispersal device. The material is constantly lifted and scattered by the lifting board device, so that it can fully contact with the hot air. At present, the lifting plate is divided into L-shaped lifting board, honeycomb type lifting board, fan-shaped lifting board, etc. according to the different production line requirements, the form of the lifting plate device is different.

4. Waste gas treatment equipment

Generally speaking, the manufacturer of electroplating sludge drying equipment will design waste gas treatment scheme according to the needs of enterprise users, set up appropriate waste gas treatment equipment in the drying production line, and use different waste gas treatment processes and various waste gas treatment equipment to achieve the purpose of purifying and discharging up to standard.

5. Other auxiliary devices

The friction transmission of the carrier wheel and the wheel belt is adopted in the electroplating sludge drying equipment, which has low transmission power and reduces the noise of the equipment. The sealing system adopts micro contact technology, which has better sealing effect and reduces dust pollution.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.