According to the drying temperature, sludge drying machine can be divided into high temperature drying and low temperature drying. High temperature drying of sludge is high drying temperature, but because high temperature drying can decompose harmful substances in sludge and volatilize them easily, it not only causes serious corrosion to equipment cylinder, but also causes more difficulty and cost for tail gas treatment when volatilized substances are mixed into gas. Therefore, when using high-temperature drying sludge, it is necessary to fully understand the characteristics of sludge and carefully select.

Low temperature drying of sludge is low drying temperature, which can not only ensure that the harmful substances in sludge are not decomposed and volatilized, but also improve the safety performance of equipment, save energy consumption, and ensure that the original organizational composition of sludge does not change after drying. At the same time, the process of tail gas treatment is greatly reduced and the treatment cost is reduced. Therefore, low temperature sludge drying method is welcomed by more and more users.

The advantages of low temperature sludge dryer are as follows

1. Energy saving

The sludge low-temperature dryer can also achieve the purpose of drying sludge by reducing the drying temperature and increasing the air volume and wind speed. With low drying temperature, energy consumption is also less, thus greatly reducing the production cost of the equipment.

2. Safety

There is no inflammable and explosive phenomenon during the whole operation of the equipment.

3. Environmental protection

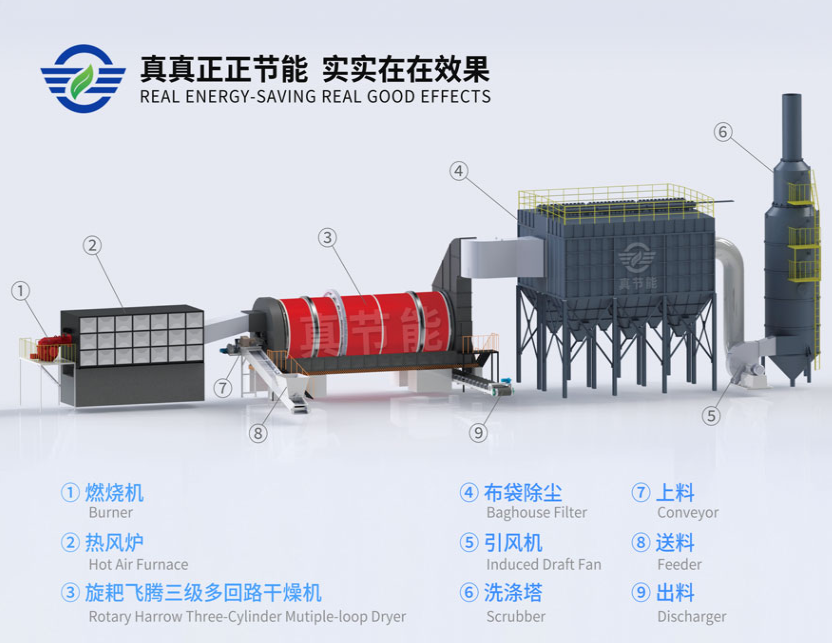

The equipment is tightly sealed, which can effectively avoid the overflow of flue gas dust inside the cylinder. At the same time, it is equipped with a professional dust removal device, which can filter, reduce and purify the flue gas dust generated in the production process, so as to make the gas meet the emission requirements and reduce the impact of the equipment on the environment.

4. Durable

Low temperature drying can effectively avoid the corrosion of the cylinder caused by sludge, not only ensure the stable operation of the equipment, but also extend the service life of the equipment.

5. Efficient

The special guiding material system is used in the equipment, which can continuously separate, stir and disperse the sludge, accelerate the contact between sludge and hot air, so as to speed up the drying speed of sludge, and ensure the quality of finished sludge after drying.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.